At the shop there are some questions we get on a regular basis. One of the most common parts of a vehicle we end up explaining to customer is the how their Ball Joints and Tie Rod Ends get excessive play and why they need to be replaced. The ball joints and Tie Rod ends play and integral part of our steering and suspension systems. To really understand how they fail we need to take a look them from the inside and see how they are designed, how they function, and where they are located.

Where is the ball joint located and what does it do? The ball joint is located between the control arms and the spindle on most applications. The ball joints operates as a pivot point between your fixed suspension and spindle which your tires mount to. These joints allow your wheels to pivot side to side on the ground. In addition to the pivot point for the wheel the ball join also carries the full weight of the vehicle except models that use a MacPherson strut suspension system. In that system the strut carries the large majority of the vehicle weight

When you look at the picture on the left you can see how these parts are designed. You have a ball that rides down in the socket of the joint. Some units like in the picture have a plastic bushing between the ball of the joint and the case it is housed in. After years of rotation in the socket and weight of the car the ball will wear into the socket or bushing creating a large opening in the socket. When this happens, that ball will move up and down and that when you have excessive wear in the ball joint.

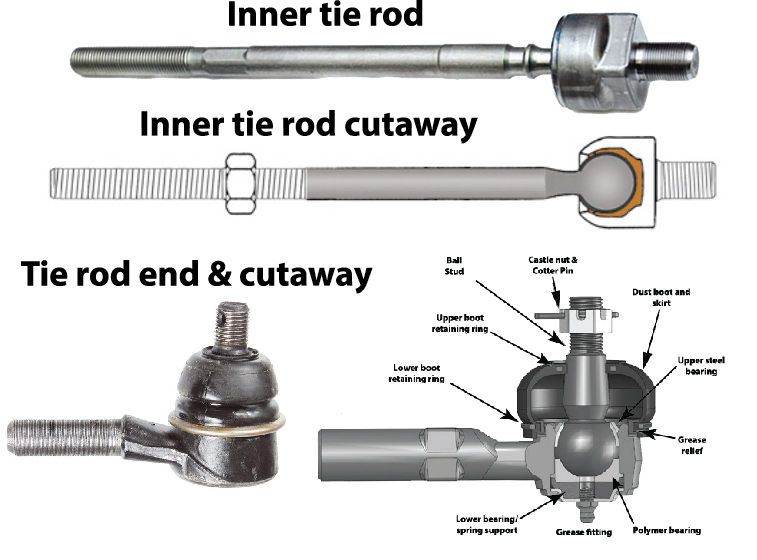

Where are your tie rod ends located and what do they do in the steering system? The tie rod end connects the steering system to the spindle. Most vehicles have inner and outer tie rod ends. When you turn your steering wheel left or right it transfers the energy from your steering gear out to the wheels in either a push or pull fashion depending on which way you are turning.

When you look at this picture above of the tie rod end cutaway you can see its internals are similar to that of a ball joint. Unlike a ball joint the tie rod ends have no weight carrying requirements. The joint at the end is under pressure while turning the steering wheel and thus moving the tires. This type of joint will also wear out the socket similar to that of a ball joint and create some play. Unlike a ball joint the tie rod end has a spring under the ball and bearing to help that joint stay nice and tight. When that spring loses its tension play can develop as well. The more play in the joint the faster the socket wears out. When this happens there is a good chance you will hear a clicking or light clunking sound coming out of the joint.